Introduction

Quality assurance is a critical aspect of any industry, ensuring that products and services meet or exceed established standards. In many sectors, having a reliable source of power is essential for maintaining quality control processes and preventing downtime. Diesel generators have long been a staple in industries where uninterrupted power supply is crucial, such as manufacturing, healthcare, telecommunications, and data centers. This article explores the role of diesel generators in enhancing quality assurance measures and ensuring business continuity.

Understanding Diesel Generators

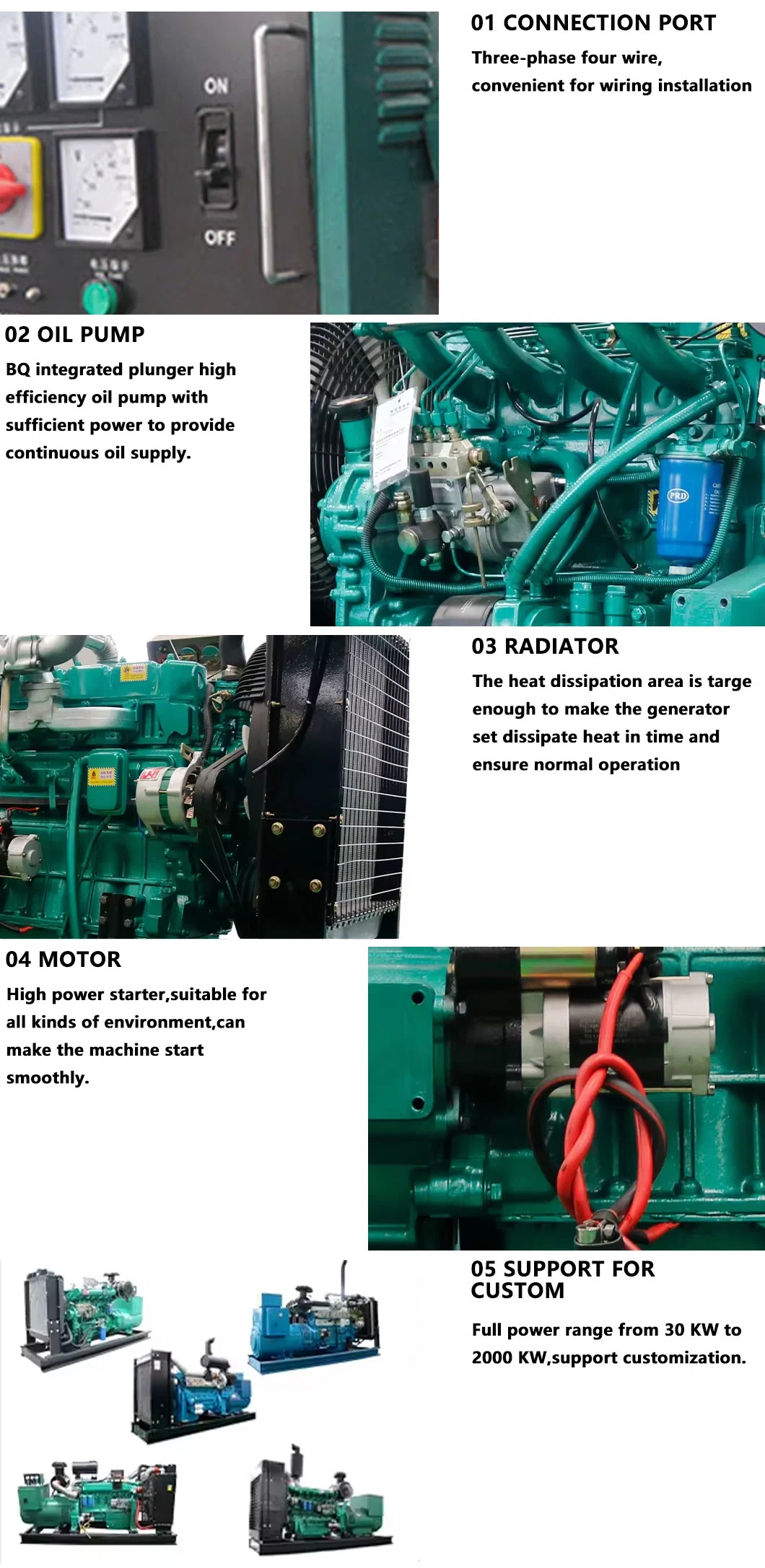

Diesel generators are a type of backup power system that uses diesel fuel to generate electricity. They consist of a diesel engine coupled with an alternator that produces electrical power. Diesel generators are known for their reliability, durability, and efficiency, making them a popular choice for applications that require continuous power supply.

One of the key advantages of diesel generators is their ability to provide backup power in the event of grid power failure. This is essential for industries where even a brief interruption in power supply can have serious consequences, such as loss of production, data corruption, or compromised safety.

Diesel generators come in a range of sizes and power capacities to suit different applications. They can be used as standalone units or integrated into a larger power distribution system. Modern diesel generators are equipped with advanced features such as automatic start/stop functionality, remote monitoring, and self-diagnostic capabilities, making them easier to operate and maintain.

Enhancing Quality Assurance

Quality assurance is a systematic process of ensuring that products or services meet specified requirements and standards. It encompasses activities such as product testing, inspection, and certification to identify and rectify defects or deviations from quality norms. In industries where quality control is critical, having a reliable source of power is essential to maintain the integrity of these processes.

Diesel generators play a crucial role in enhancing quality assurance measures by providing a reliable and uninterrupted power supply. Here are some ways in which diesel generators contribute to quality assurance:

1. Uninterrupted Power Supply: In industries where quality control processes are automated or reliant on electronic systems, any interruption in power supply can disrupt operations and compromise the quality of products or services. Diesel generators ensure that critical systems remain operational during grid power outages, preventing downtime and maintaining quality standards.

2. Backup for Testing Equipment: Quality assurance often involves testing equipment such as spectrometers, chromatographs, or precision measuring devices. These instruments require a stable and continuous power supply to function accurately. Diesel generators act as a backup power source for testing equipment, ensuring that quality control processes can continue even during power failures.

3. Climate Control and Refrigeration: In industries such as pharmaceuticals, food processing, or healthcare, maintaining specific temperature and humidity conditions is essential for quality assurance. Diesel generators power climate control systems, refrigeration units, and cold storage facilities, ensuring that temperature-sensitive products remain within specified ranges.

4. Emergency Lighting and Security Systems: Quality assurance extends beyond product quality to include workplace safety and security. Diesel generators power emergency lighting systems, fire alarms, surveillance cameras, and access control systems, ensuring that critical safety measures are operational during power outages or emergencies.

5. Data Protection and Backup: In industries where data integrity is paramount, such as finance, healthcare, or IT, diesel generators play a crucial role in ensuring continuous power supply to data centers, servers, and backup systems. This safeguards critical data from loss or corruption, maintaining quality assurance standards for information security and compliance.

6. Reducing Downtime and Losses: Quality assurance is not just about meeting standards but also about minimizing risks and losses. Diesel generators help businesses avoid costly downtime, production delays, or financial losses that can result from power outages. By providing a reliable backup power source, diesel generators contribute to business continuity and operational resilience.

https://www.lkpowerplant.com/product/robust-240kva-power-solution-diesel-generator-set-for-commercial-projects/ and Best Practices

Several industries have successfully integrated diesel generators into their quality assurance strategies to enhance reliability and compliance. Here are some case studies and best practices illustrating the benefits of diesel generators in quality assurance:

1. Manufacturing Sector: A leading automotive manufacturer relies on diesel generators to power its production lines and quality control systems. By ensuring uninterrupted power supply, the company maintains optimal manufacturing conditions, reduces defects, and meets stringent quality standards. Regular maintenance and testing of diesel generators are key to ensuring readiness during emergencies.

2. Healthcare Facilities: Hospitals and healthcare facilities use diesel generators to power critical equipment, such as life support systems, operation theaters, and diagnostic machines. In the event of a power outage, diesel generators kick in seamlessly, ensuring that patient care is not compromised. Regular load testing and fuel management are essential to guarantee the reliability of backup power systems.

3. Telecommunications Networks: Telecommunication companies rely on diesel generators to power cell towers, data centers, and network infrastructure. By incorporating redundant power sources and backup systems, telecom operators ensure that communication services remain operational during emergencies or natural disasters. Remote monitoring and predictive maintenance help identify and address potential issues proactively.

4. Data Centers: Data centers are the backbone of modern businesses, hosting critical applications, databases, and digital assets. Diesel generators are a vital component of data center infrastructure, providing backup power to servers, cooling systems, and security equipment. Implementing a comprehensive disaster recovery plan, including regular generator testing and fuel storage protocols, is essential for data center quality assurance.

5. Remote Locations: Industries operating in remote or off-grid locations, such as mining, oil and gas, or agriculture, rely on diesel generators for primary or backup power supply. These generators are often customized to withstand harsh environments and extreme weather conditions, ensuring continuous operation in challenging settings. Proper maintenance, fuel filtration, and monitoring are crucial for remote site quality assurance.

Conclusion

Diesel generators play a critical role in enhancing quality assurance measures across various industries by providing reliable backup power supply. From manufacturing to healthcare, telecommunications to data centers, businesses rely on diesel generators to maintain operational continuity, protect critical systems, and ensure compliance with quality standards. By integrating diesel generators into quality assurance strategies and implementing best practices for maintenance and testing, organizations can safeguard against power disruptions, minimize risks, and uphold the highest standards of quality and reliability.